A Biological Makerspace

Credit: Callie Richmond

By Marc Airhart.

In early 2020, scientists at UT Austin were deep into building a unique facility on the Forty Acres, a turbo-charged, biotech playground with a focus on rapid scientific discovery. The biological foundry, as it was called, was part of a partnership in synthetic biology research between The University of Texas at Austin and the U.S. military. It just so happened that the foundry’s founding came along at the same time as the worst biological event in generations: COVID-19.

Fighting biological threats is a high priority of the U.S. military and one of four main focus areas for a new partnership with Army Research Laboratory South. When the pandemic began, there was no time to waste for UT Austin biological researchers. An initial goal was to identify, as quickly as possible, the antibodies in patients that could help wipe out a corona virus infection.

Collecting and analyzing blood samples from COVID patients, the researchers analyzed samples, at first manually, then as more of the missing pieces to the foundry puzzle fell into place, using automated systems in the facility. Within months, that work led to a potential new treatment for COVID-19, highlighting the value of universities and outside partners working together in times of crisis.

Leveraging Collaboration

The U.S. Combat Capabilities Development Command Army Research Laboratory (ARL) is the Army’s national research laboratory; it focuses on fundamental research, cutting-edge scientific discovery and technological innovation. ARL South is one of several regional hubs within ARL, with hubs also in the west, northeast and centrally.

“Establishing regional partnerships like the one we have with UT Austin,” says Heidi Maupin, ARL South’s regional lead, “enabled Army researchers to work side by side with esteemed university researchers. Our collaboration leverages access to cutting-edge facilities, data and elite subject-matter experts to solve unique Army problems in an accelerated manner.”

Credit: Callie Richmond

ARL South and the other regional labs address a key challenge facing the military: the slow lag between fundamental research happening at universities across the country and the application of the new knowledge and experimental approaches they create within the Army. The research partnerships exist to pave the way for new technology directions, new perspectives, new industry collaborators and, ultimately, new discoveries to help the military solve current and future challenges in preparedness.

ARL South, headquartered on UT Austin’s J.J. Pickle Research Campus in north Austin, interacts with leading campus researchers in synthetic biology, as well as networking, robotics, artificial intelligence and materials development.

“There’s a definite advantage to being in the heart of the entrepreneurial culture that is home to Austin, motivating our own researchers to take risks and embrace innovation.”

“UT Austin was selected as the location to plant our ARL South flag because of the proximity to Austin’s broad tech startup community,” Maupin says. “There’s a definite advantage to being in the heart of the entrepreneurial culture that is home to Austin, motivating our own researchers to take risks and embrace innovation as we strive for transformational technical capabilities that will protect our nation.”

Another key benefit of these kinds of partnerships is that students and postdocs can gain skills and experience working on real-world problems and explore career opportunities outside of academia.

Putting Biology to Work

Besides countering biological synthetic biologists working in the partnership – from faculty scientists to graduate students – are exploring ways to adapt the natural machinery of life to make advanced materials with useful properties, such as fostering sustainability.

For example, one project involves developing toolkits that allow for controlling gene expression in microbes and plants so they produce materials needed at industrial scale, such as for lighter, stronger or more camouflaged armor for soldiers. The project also might yield sensitive biosensors that can detect the presence of biological or chemical weapons in the field. Andy Ellington, a professor of molecular biosciences, and his collaborators are partnering with ARL South to develop processes that can convert waste into useful products.

“The Army always has interests in bioremediation,” Ellington says. “The Army wants to be able to both clean up after themselves and ‘live off the land.’”

The researchers are also using machine learning to make plastic waste-degrading enzymes more stable and work in real-world conditions. These advances will be especially important when moving biology outside the lab and into the real environment.

Antibodies to the Rescue?

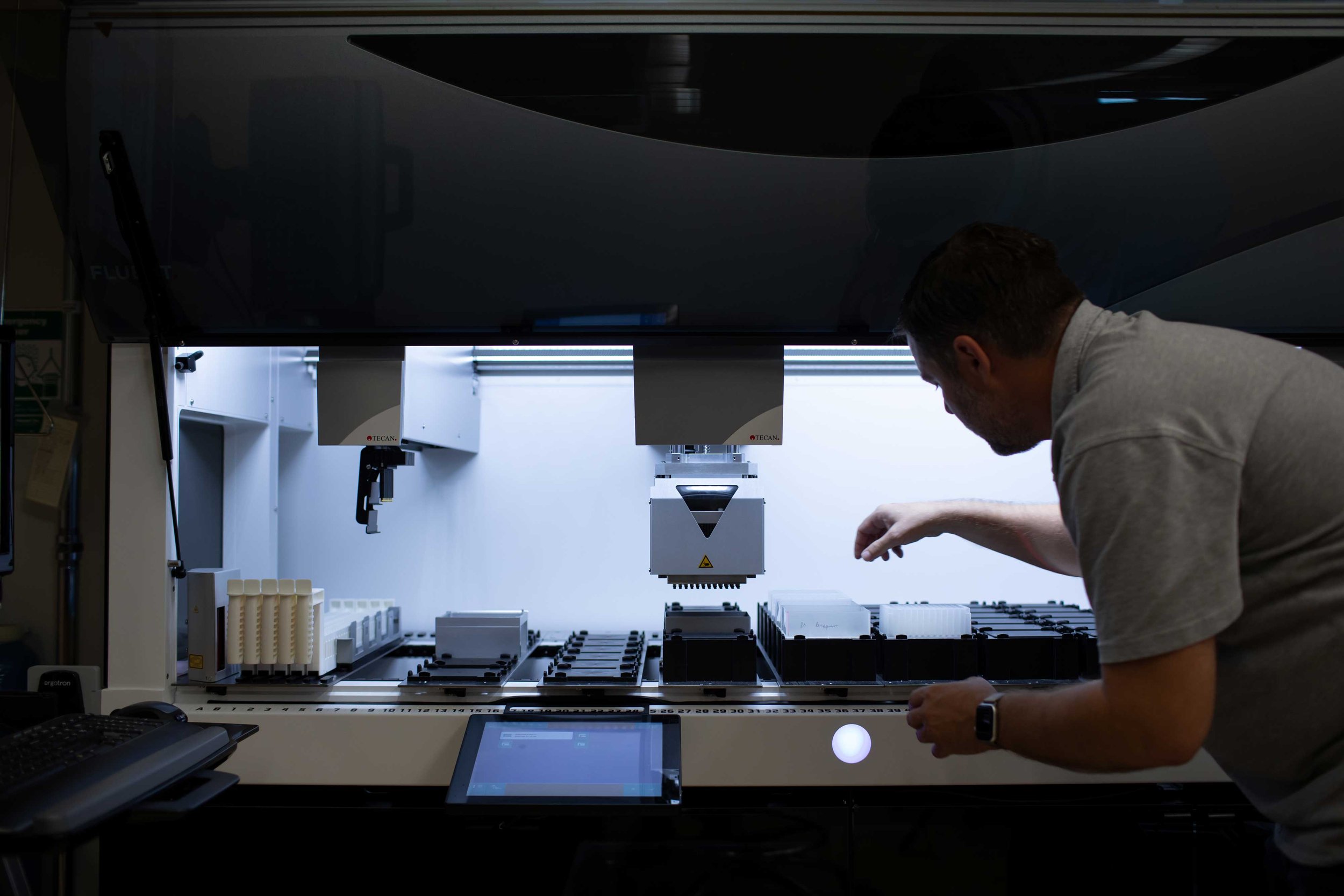

The foundry facility offers 2,500 square feet with state-of-the-art equipment capable of high-throughput screening and directed evolution. It houses capabilities typically dispersed across multiple university labs – for sequencing and synthesizing DNA, sorting individual cells, sorting and analyzing the chemical constituents of materials and editing the genetic code of plants and microbes. Plus, it’s efficient: in the time it takes a graduate student to transfer a single sample from one tube to another via pipette, the facility’s liquid- handling robot can transfer 384 samples.

Credit: Callie Richmond

Researchers in the partnership are combining such automation with the approach called directed evolution – an iterative process that starts with generating a host of mutated versions of a molecule or organism, selecting ones that best fit certain criteria, and then repeating – to accelerate scientific discovery. Their goal is to analyze simultaneously 1 billion unique variants of an enzyme in a single tube en route to selecting the 10,000 most promising versions for further iteration.

A number of top UT Austin labs in molecular biosciences and engineering are involved in the COVID-19 antibody research work described at the beginning of this article. In addition to Ellington, they include molecular bioscientists Jason McLellan, Ilya Finkelstein, George Georgiou, and Edward Marcotte; chemical engineers Hal Alper and Jason Lavinder; and recent UT Austin researcher Jimmy Gollihar.

The long-range vision of the ARL South partnership with UT Austin was instrumental as the team discovered an antibody produced naturally by an infected COVID-19 patient robustly neutralizes the virus in cell cultures. The researchers are currently testing in animals, and if all goes well, clinical trials in humans could begin this year.

See how the team made an enzyme that can degrade, in a matter of hours, plastic that could otherwise take centuries to break down: